While there are many more ideas we could discuss for consideration in your facility, the final item on our list is Get Involved. More specifically, get involved with learning and observing […]

Get Involved

While there are many more ideas we could discuss for consideration in your facility, the final item on our list is Get Involved. More specifically, get involved with learning and observing […]

You can randomly look around for inventory that appears to have been around for a while. If the inventory has excess dust on the boxes chances are it has been there too long. […]

In an earlier blog we discussed ABC profiles and cube movement distribution. Through this analysis you should be able to determine if products are frequently ordered together. If you do see a significant correlation between products, consider storing the products together to help reduce overall travel time per pick tour. If the pick correlation frequency […]

Paying attention to the fastest selling items to make sure they are located in the most advantageous picking position will generate significant labor cost savings. If available space is a concern, slotting will also help improve storage utilization by focusing on the slowest movers to see if their assigned bin space can be reduced. […]

In Part two of our Space Utilization series, “The Supply Chain Doctor” Chris Barnes discusses more ways you can utilize space in your Warehouse. Think Cubic Feet The impact of using vertical storage space depends on your current storage clear height and product stack-ability restrictions. For example, in the beverage industry, a stack height limitation […]

In the first of a two part series, The Supply Chain Doctor Chris Barnes will be discussing various Space Utilization concepts. […]

Most people want to do a good job, know where they stand, and be recognized for their performance. One easy way to accomplish this and also improve productivity is to develop a simple process measuring performance and posts results in the warehouse. It does not have to be a complicated process. Simply measuring and recording […]

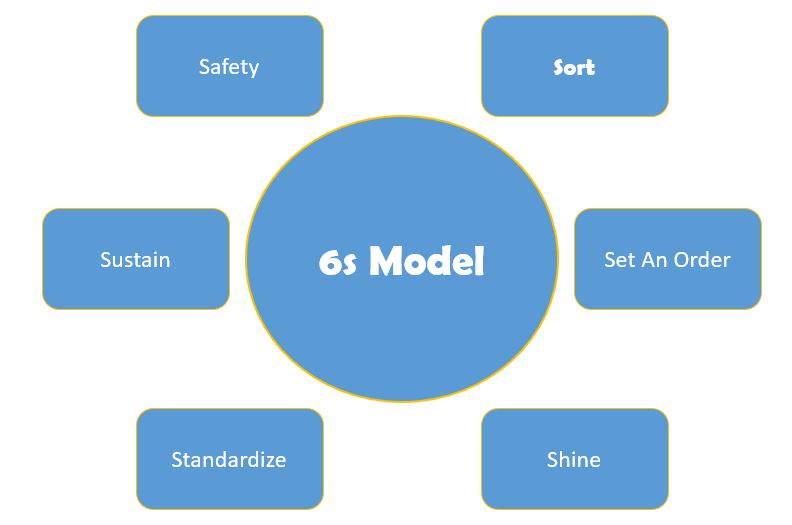

At its core 6S supports establishing a visual workplace and is a part of Kaizen – a system of continual improvement – a component of getting lean. […]

To celebrate our new website Impact WMS are launching our new Blog section.

Check out our first post where we will be outlining topics for the upcoming weeks. […]