Between surging labor costs, a shortage of workers, and facility rents climbing across North America, there’s not a warehousing operation today that isn’t operating with ever shrinking margins. Fortunately, a warehouse manager can harness the benefits of real-time visibility that can have a dramatic effect on the bottom line. WHAT IS REAL-TIME VISIBILITY OF WAREHOUSE […]

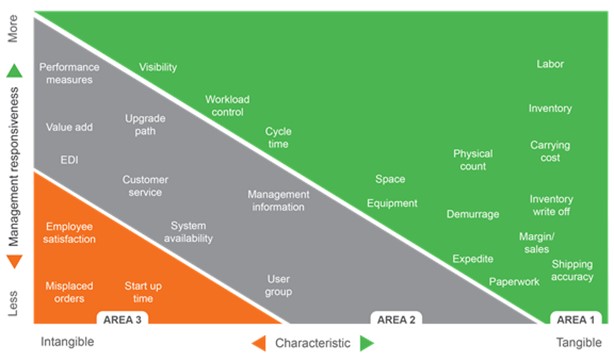

THE BENEFITS OF REAL-TIME VISIBILITY TO THE WAREHOUSE OPERATION