A straight-forward way to improve pick labor productivity is to eliminate the travel back and forth to the office and the shipping/packaging areas between order picks. One way to accomplish this is to have one operator pick multiple orders at the same time, or Cluster Pick, if possible. Cluster Picking is a pick method where an operator picks to cartons/totes for multiple orders during one pick tour. Cluster Picking is especially successful when the same item or items are frequently included in multiple orders AND the total cube of multiple orders can be easily handled. For example, if your orders typically result in pallet loads, the benefits of moving and managing multiple pallets will be negligible, but possible. If however, your orders typically fit into a small standard carton size, handling 4 to 6 cartons during the pick tour is quite possible.

Cluster Picking can significantly reduce pick labor requirements but may require additional administrative management if not support by an automated picking system.

When designing a cluster pick process, consideration needs to be given to the tradeoffs between reduced travel time and excess handling requirements. At some point there will be diminishing marginal return on cluster size.

Pre-routing

Pre-routing is the process of mapping out the pick travel path to reduce wasted motion and travel during the pick. The sequence of items on a standard customer order may not reflect the bin of the material in the warehouse. Consequently, using a standard customer order as the picking document usually results in an inefficient picking process. The ratio of time spent traveling to time spent actually picking material is extremely high because there is no logical sequence to the pick route. An excess amount of backtracking might be required to pick an item that was already passed in the process if the items are stored randomly and there is no pre-routed sequence logical applied to the pick tour. To demonstrate the benefits of pre-routing an order, let’s use an example of a grocery shopping list. You might have items on the shopping list in random order (milk, pickles, bread, eggs, soda, and cleaning wipes). Sometimes the list is developed based off which item you remembered to add first. There is no rationale. At this point the list serves the purpose of a memory jogger to remind you what to buy on the next trip to the store.

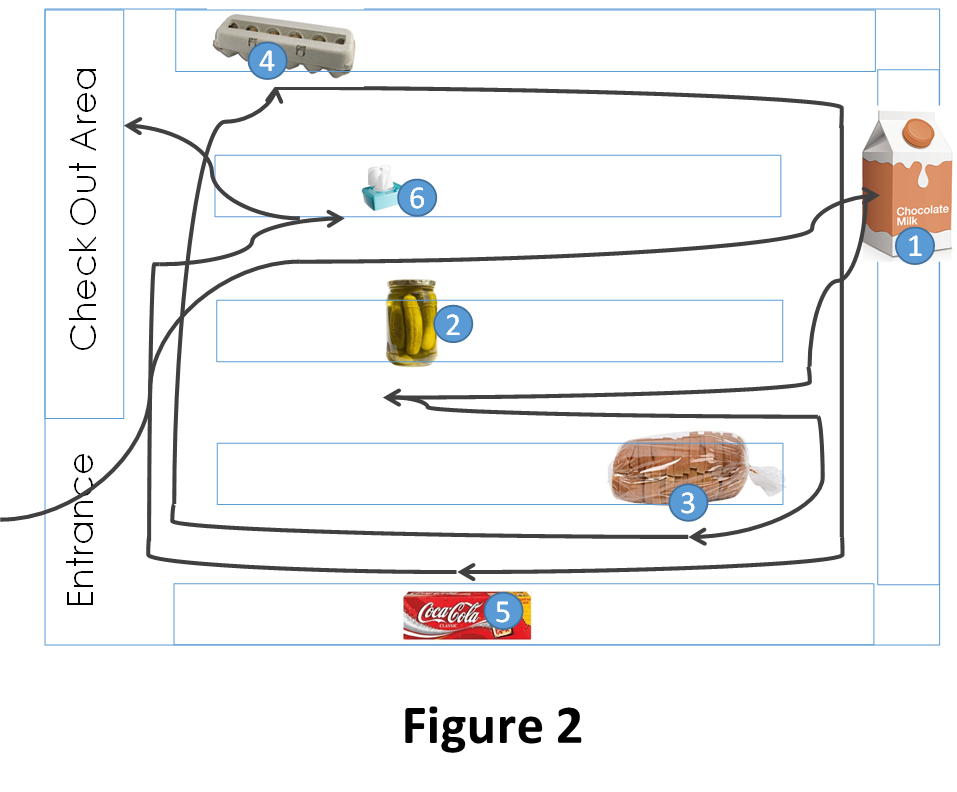

If you go to the store with the list you originally made, the travel through the store may look something like Figure 2…

- Walk in and find the milk,

- next go to the pickles,

- from there find the bread,

- eggs are next,

- Coca Cola for the weekend,

- cleaning wipes,

- and finally proceed to checkout

This looks confusing and chaotic.

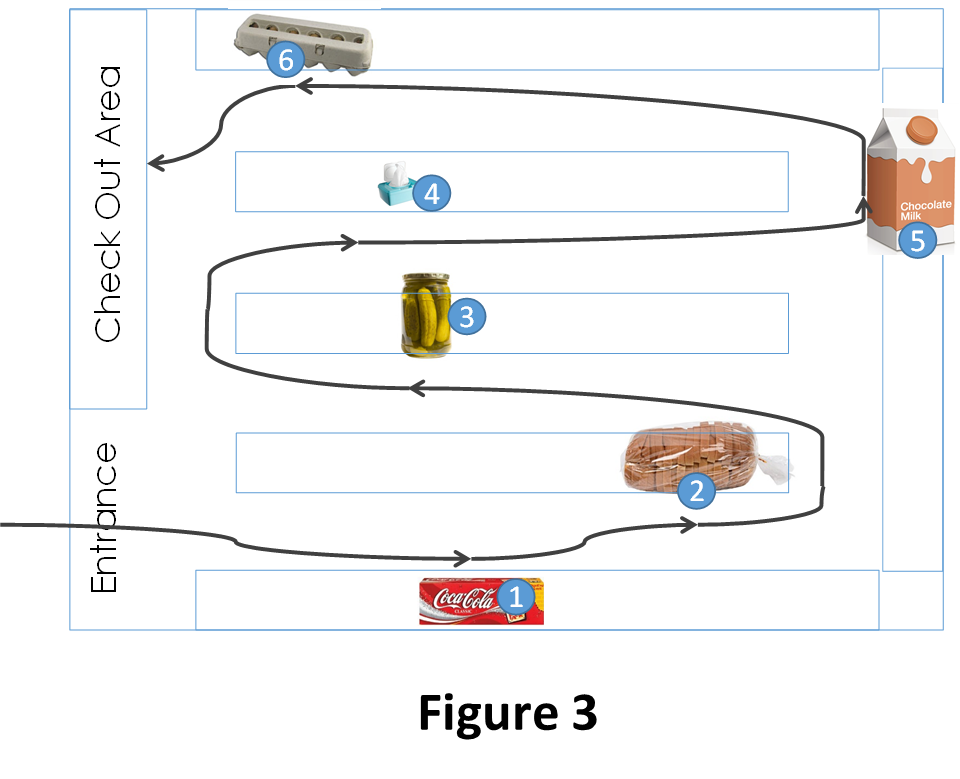

If, however, the order was pre-routed based on bin sequence the travel path might look like Figure 3…

- Walk in and find the Coca Cola;

- bread

- pickles

- cleaning wipes

- milk

- eggs

- and proceed to checkout

You might agree this is much more organized and efficient? And it works well if you want to keep the milk and eggs refrigerated as long as possible.

But can you think of an example why this concept might need some tweaking?

Well, if you are going to buy a lot of soda you might want to get this last to keep from having to move the heavy load around the store. On the other hand, you probably don’t want to stack the soda on top of the bread and eggs.

These same principles and considerations apply when planning your warehouse picking strategies.