With the exponential growth of e-commerce, everyone’s customer-base is used to fast and accurate deliveries. With rising customer expectations, the margin of error for a warehouse has never been closer to zero. As warehouse managers navigate this new reality, it is critical to know how WMS helps reduce errors and mis-shipments to customers.

COMMON MISTAKES ON THE WAREHOUSE FLOOR

As explored in The Costliest Warehousing Mistakes, poor processes or signage can lead to a cascade of issues. Outbound inventory needing to be reshelved. Disorganized aisles and racks that become impossible for pickers to quickly navigate. Inventory distortion that costs businesses financially while inadvertently misleading customers on stock availability.

As the expression goes, “to err is human.” When you rely solely on paper and pen or manual spreadsheets to track every element of your operation, you invite mistakes at every step of the operation. But few might be more costly than mis-shipments.

WHAT IS A MIS-SHIPMENT?

A mis-shipment can occur in several different ways.

- A package is sent to a customer that contains the wrong items.

The wrong order details are relayed from your sales portal to your pickers on the floor. Or maybe a picker loses focus and grabs the wrong item. - An order is sent with the correct contents, but the wrong quantity.

Somewhere between your customer placing an order and your employee fulfilling it, a miscount has occured. This often occurs through mental lapses of a picker or a ‘broken telephone’ effect when verbally relying order details. - The wrong order is delivered to the wrong customer.

Miscommunication or confusion can lead to the wrong label going on the wrong box. Instead of one mis-shipment, this error leads two or more customers failing to get their correct orders. - Delivering the Order After the Established Arrival Date

This can occur for a number of reasons. A leading cause is relying on a manual cycle count. Having an out-of-date picture of your inventory can lead to promising availability and a delivery date that is not possible.

THE COST OF MIS-SHIPMENTS

Think about the financial impact of just one mis-shipment:

- You have the initial shipping cost

- Your team must process and pay for the return shipment

- The shipping materials such as boxes or bubble wrap will most likely not be reuseable and must be replaced.

- You tie up staff to re-fulfill the initial order

…and all this to say nothing of the long-term monetary damage to your brand’s reputation.

A recent study (Honeywell, 2020) found that the average mis-shipment costs a company $100. If your mis-shipment rate is higher than the industry average of 2 to 3%, this can equal millions of dollars in lost revenue.

While a good returns process is important, it is really fixing a problem after it has happened. The most successful warehouse managers have pivoted to building a system that prevents these mistakes before they happen.

PREVENT MIS-SHIPMENTS WITH A WMS

When your team is busy putting out fires caused by mis-picks and mis-shipments, they are not just wasting time but money.

Say you staff a warehouse of 50 workers per shift and each of them spends on average 20 minutes handling returns or re-fulfilling orders caused by a mis-shipment. That would come out to 1000 minutes a day or 16 hours. Now multiply that across the number of work days in a year and your employees are wasting 4,160 hours a year. Okay, now take a moment to multiply your employees’ hourly rate by 4,160. It’s not a pretty number, is it?

Arming your warehouse staff with a barcode scanner might seem like such a simple thing, but it’s the ultimate weapon to cut those wasted hours close to zero.

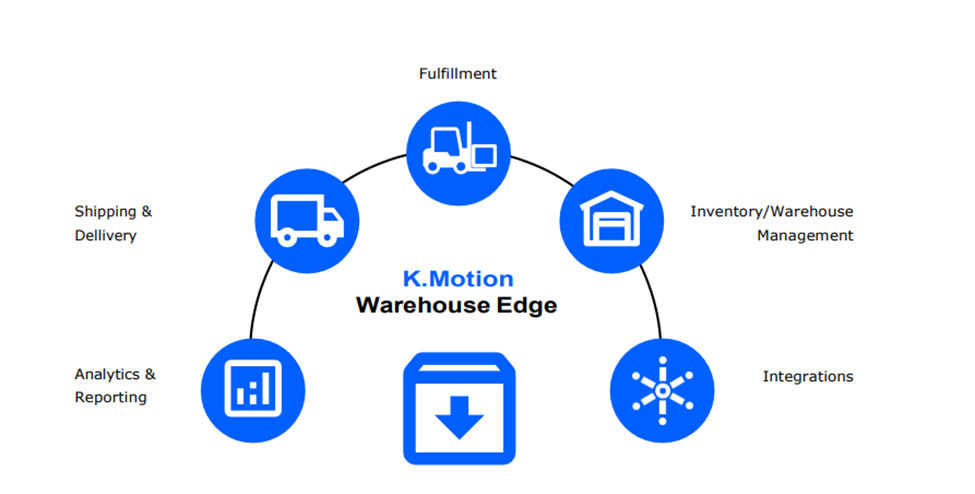

With K.Motion Warehouse Edge WMS, labeling your racks and bins with SKUs and equipping your staff with handheld scanners means that whether a picker is rushed or distracted, they will know the moment they scan that item out whether they have grabbed what your customer ordered.

It is a game changer for accuracy. Scanning the bar code at each stage of the fulfillment process eliminates the risk of human error.

SHIPPING TRANSPARENCY AND COMMUNICATION

Shipping the correct items is just one factor in improving customer satisfaction. A WMS is not just about managing your warehouse more efficiently, it is a pivotal technology to provide your customer with transparency. Once a customer has placed an order, they want to be able to know it’s movements and ETA.

That visibility is next to impossible if you still rely on your employees to document every shipment by hand. Fortunately, when a WMS is implemented, you can automate shipping notifications and delivery updates right from the moment an item is picked and packaged.

When a customer feels informed and involved at each stage, they are more understanding when an unforeseen delay occurs.

ACCESSING DATA INSTANTOUSLY THROUGH A WMS

Cycle counts are critical to avoiding the dreaded stockout status that sees customers turning to one of your competitors. They also save a warehouse from overstock tying up critical space and resources in your warehouse (for more, see our recent post ‘What is a Cycle Count?’). However, manual counts require sections of a warehouse to go down for lengthy periods of time while employees do inventory. For this reason, a manual count can only be done so often – creating time sensitive holes in your data.

Utilizing K.Motion Warehouse Edge from Impact WMS, each product picked creates a data point, generating a real-time cycle count. With minute-by-minute data, you can know exactly where your inventory stands and what items are in demand.

This real-time picture is not only helpful for managing your warehouse. Through processes such as integrating your WMS with your CRM to create personalized recommendations for your customers based on their past purchases, it can empower your sales team to craft targeted marketing campaigns leaving customers feeling seen, understood, and valued.

CUSTOMER SATISFACTION THROUGH A WMS

To gain a critical competitive advantage, a company must look at a WMS not just as a back-end system for their warehouse, but as a strategic tool that impacts every aspect of their business. Efficiency, resource allocation, customer satisfaction, and brand loyalty, that is K.Motion Warehouse Edge. Through implementation, a facility reduces waste, minimizes errors, and streamlines operations.

A well-run warehouse is the backbone of a successful business. Investing in a leading-edge warehouse management system is not just an investment in your facility, but an investment in your customer relations and ultimately in your brand’s reputation.