On a recent facility tour I observed a unique approach to storing individual cigars. This neat diamond rack configuration was designed to easily store various types and sizes of cigars in a small area. During a discussion with the rack designer we mentioned the pro’s and con’s of the design:

Pro’s: Good density, ease of implementation, ease of accessibility (good use of the strike zone), cost (they are already paid for)

Con’s: First in First Out (FIFO) inventory rotation constraints, flexibility, and difficult to retrieve product (cigars becoming stuck in corners)

After the discussion, I reached out to my network of some of the best warehouse consultants in the business to get their input on storing small items with a preference for FIFO inventory management. Following are ideas I got back for consideration:

- Plastic dividers on small beam racking. This is a simple concept I saw where the company purchased small clear plastic dividers to apply to shelving using Velcro in the back and magnets on the front. The plastic dividers were purchased on e-Bay.

- Traditional gray small bin shelving with cardboard or plastic bins. The next iteration is to reduce the space consumed by the physical shelf. Given the light weight of the cigars small bin shelving with either cardboard dividers or plastic bins are an option. These are common in retail auto parts back rooms.

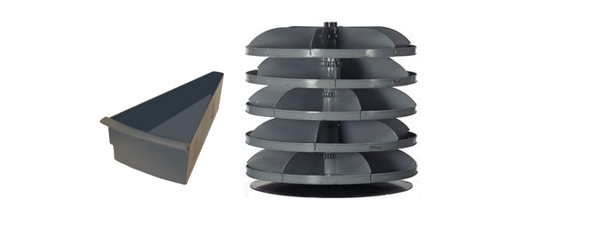

- Rota bins similar to what you used to see in the hardware stores for storing nuts-and-bolts. These circular units consume a small footprint and you can add smaller plastic bins to further subdivide the shelves/bays. Funny story…early in my consulting career I referenced this medium as a carousel when proposing storage options. I was almost laughed out of the meeting until I was able to level set exactly what I was referring to. Rota bins are much more cost effective than carousels.

In part 2, we will introduce a few more ideas for storing small items and provide a brief alternative comparison