Storing Small Items – Part 2

Last month we introduced a few ways to store small items including custom made dividers, plastic dividers on small beam racking, traditional small bin shelving and rotabins. This month we provide a few more small items storage ideas and end with a general comparison. Straw/pencil dispensers are a very out of the box concept but […]

Store Product Picked Together, Together

In an earlier blog we discussed ABC profiles and cube movement distribution. Through this analysis you should be able to determine if products are frequently ordered together. If you do see a significant correlation between products, consider storing the products together to help reduce overall travel time per pick tour. If the pick correlation frequency […]

Cluster Pick When Possible

A straight-forward way to improve pick labor productivity is to eliminate the travel back and forth to the office and the shipping/packaging areas between order picks. One way to accomplish this is to have one operator pick multiple orders at the same time, or Cluster Pick, if possible. Cluster Picking is a pick method where […]

Know Your Order Profile

A basic principle to optimizing warehouse space is evaluating and selecting the most space efficient storage equipment. Using more dense storage equipment is a key factor to reduce space requirements. An analysis of your products inventory levels and cubic order activity should be performed to accurately define the storage requirements in reserve and the forward […]

Körber: What Impact WMS Customers Should Know

In August 2017, Körber acquired HighJump, which is now managed under its business area, Körber Supply Chain. Körber brings together a number of companies, including 12 supply chain technology providers (four in automation and eight in software and consulting). These 12 providers include two WMS providers that have multiple WMS solutions. HighJump (named Körber since […]

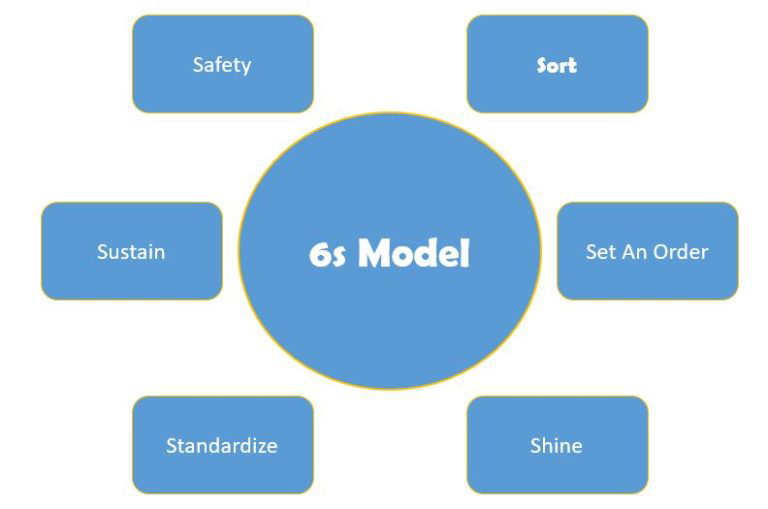

Easy Warehouse Improvement Idea: Apply 6S

6S has long been part of successful manufacturing processes. A natural extension is applying these principles in warehousing and distribution. The pillars of 6S are: Sort – eliminate whatever is not needed Set In Order – organize, identify and arrange everything in a work area Shine – regular cleaning and maintenance Standardize – make it […]