Benefits of Real-Time Warehouse Visibility

Between surging labor costs, a shortage of workers, and facility rents climbing across North America, there’s not a warehousing operation today that isn’t operating with ever shrinking margins. Fortunately, a warehouse manager can harness the benefits of real-time visibility that can have a dramatic effect on the bottom line. WHAT IS REAL-TIME VISIBILITY OF WAREHOUSE […]

Gamification of Your Warehouse

Playing games at work might not be what you immediately think of when it comes to improving productivity and engagement amongst your employees, yet that is exactly what is fast becoming an industry go-to. It is a technology known as as gamifying, and the gamification of your warehouse can not only improve your employees’ output […]

What is a Cycle Count?

Your warehouse is full of inventory, but how do you get an accurate picture of what is on any given shelf tomorrow? Next week? Later this afternoon? You could get your warehouse staff to conduct a physical inventory, auditing your entire facility’s stock. But unless you are running a small operation with limited SKUs, a […]

The Costliest Warehousing Mistakes

There has never been a more demanding or challenging time to run a warehouse. Staying competitive means navigating supply chain issues, the demand of a booming online sales market, and expectations of speedy delivery. Each operation has unique quirks, however, there are a few costly warehousing mistakes that every facility risks falling prey to. Avoiding […]

Five Ways a WMS Improves Customer Service

A product’s journey might start with sales and marketing, but it is quickly in the hands of your warehouse. Ensuring that your customer has a hassle-free, convenient experience goes well beyond the point of sale. A warehouse management system is not just a crucial tool for operating your facility day-to-day. Let’s look at five ways […]

The Benefit WMS Building Blocks – Inventory Accuracy

A Warehouse Management System (WMS) is a foundation for improved operational efficiency, providing a series of building blocks that will act as a basis for efficient warehousing operations. Today we will look at one of the primary building blocks a WMS provides; Improved inventory record accuracy and the reduction in data processing errors that result […]

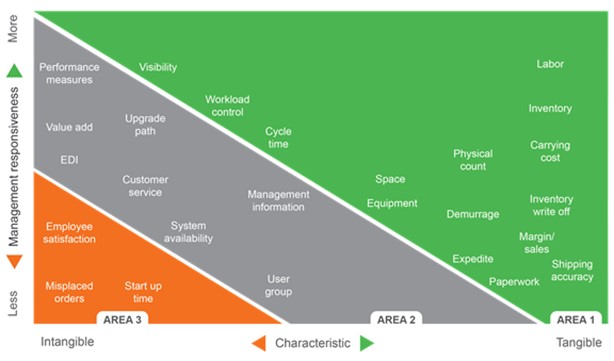

WMS Benefit Classification

Along with the tangible and intangible characteristics, a benefit should be measured on management’s general level of responsiveness to the benefit. The level of aggressiveness to use in pursuing the benefit will vary by company and/or project. It is critical to discern, in advance, management’s willingness to consider the presented benefits. For example, improved customer […]

The Road Ahead: Justifying a WMS

A successful warehouse management system (WMS) implementation can provide an 18-24 month return on investment. A WMS also serves as a foundation for instituting a continuous improvement culture and facilitates on-going annual benefits ranging from 5-10%. For some companies, justification in a WMS is a matter of survival. Having the right material available at the […]

Directed Put-away – No Location Found

In the December 2021 post we outlined the potential need for operators to override the system directed put-away instructions and the need for having a “trouble” location. In both these examples the primary objective is to keep operators moving and processing productive tasks, in this case putting product away and moving to the next task. […]

Directed Put-away – No Location Found

In recent posts we discussed taking advantage of technology to help with product put-away. Directed put-away removes the routine and tedious decision making tasks from operators allowing them to be more productive. A good warehouse management system (WMS) should allow management to define various put-away rules the computer will use when determining the best put-away […]