The Benefit WMS Building Blocks – Inventory Accuracy

A Warehouse Management System (WMS) is a foundation for improved operational efficiency, providing a series of building blocks that will act as a basis for efficient warehousing operations. Today we will look at one of the primary building blocks a WMS provides; Improved inventory record accuracy and the reduction in data processing errors that result […]

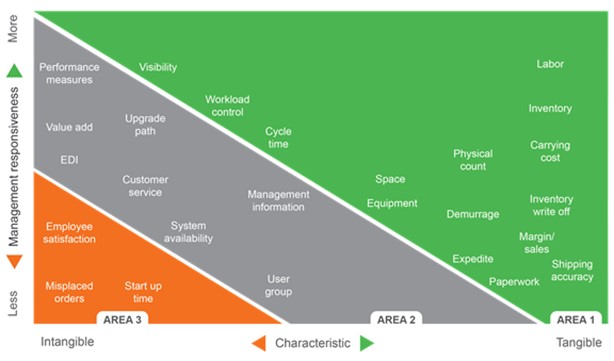

WMS Benefit Classification

Along with the tangible and intangible characteristics, a benefit should be measured on management’s general level of responsiveness to the benefit. The level of aggressiveness to use in pursuing the benefit will vary by company and/or project. It is critical to discern, in advance, management’s willingness to consider the presented benefits. For example, improved customer […]

The Road Ahead: Justifying a WMS

A successful warehouse management system (WMS) implementation can provide an 18-24 month return on investment. A WMS also serves as a foundation for instituting a continuous improvement culture and facilitates on-going annual benefits ranging from 5-10%. For some companies, justification in a WMS is a matter of survival. Having the right material available at the […]

Put-away, Directed vs. Suggested

In recent months we outlined several advantages of using a warehouse management system (WMS) to direct product putaway to minimize operator decision making requirements. We pointed out the potential improvements in compliance, operator productivity, and overall space utilization. But as the saying goes, there is no such thing as a free lunch. In this example […]

Reasons for System Directed Put-away

Last month we discussed the use of boom rooms in the warehouse and the idea of using system directed putaway to keep flammable product in a safe space. There are many other reasons you might want to use your warehouse management system to help determine where product should be stored. Product picked together Labor consumes […]

Lean and Safety – Stop, Look & Point

Safety and Lean can and should go hand in hand. I recently did a lean tour of a large distribution center. Along with seeing many lean process ideas I learned they had a strong focus on employee safety. For instance, one thing everyone did (and we received training pre-tour) was the practice of Stop, Look […]

Cluster Pick When Possible

A straight-forward way to improve pick labor productivity is to eliminate the travel back and forth to the office and the shipping/packaging areas between order picks. One way to accomplish this is to have one operator pick multiple orders at the same time, or Cluster Pick, if possible. Cluster Picking is a pick method where […]

Warehouse within a Warehouse

Using a Forward Pick strategy helps keep a smaller volume of inventory in easily accessible bins (Forward Pick) with the excess stock in remote bins (Reserve Storage) (Figure 1). The Forward Pick zone in a warehouse functions as a “warehouse within a warehouse”: many of the most popular SKUs are stored there in small amounts, […]

Know Your Order Profile

A basic principle to optimizing warehouse space is evaluating and selecting the most space efficient storage equipment. Using more dense storage equipment is a key factor to reduce space requirements. An analysis of your products inventory levels and cubic order activity should be performed to accurately define the storage requirements in reserve and the forward […]

Easy Warehouse Improvement Idea: Apply 6S

6S has long been part of successful manufacturing processes. A natural extension is applying these principles in warehousing and distribution. The pillars of 6S are: Sort – eliminate whatever is not needed Set In Order – organize, identify and arrange everything in a work area Shine – regular cleaning and maintenance Standardize – make it […]