Get Involved

Over the past eleven months we reviewed several low-hanging fruit process improvement concepts to help improve your warehouse performance. You can read more about these concepts here. While there are many more ideas we could discuss for consideration in your facility, the final item on our list is Get Involved. More specifically, get involved with learning and […]

Pass the White Glove Test

You can randomly look around for inventory that appears to have been around for a while. If the inventory has excess dust on the boxes chances are it has been there too long. Alternatively, if you plan to come back to the warehouse you can mark one of the cases then when you return (maybe […]

Store Product Picked Together, Together

In an earlier blog we discussed ABC profiles and cube movement distribution. Through this analysis you should be able to determine if products are frequently ordered together. If you do see a significant correlation between products, consider storing the products together to help reduce overall travel time per pick tour. If the pick correlation frequency […]

Space Utilization Part One

Do you have too much warehouse space? Chances are you are either out of space or getting close to it. It happens all the time, inventory (and other stuff) tends to expand to fill the amount of available space. When you do run out of warehouse space there are many options to consider including expanding […]

Is your Warehouse productive?

Most people want to do a good job, know where they stand, and be recognized for their performance. One easy way to accomplish this and also improve productivity is to develop a simple process measuring performance and posts results in the warehouse. It does not have to be a complicated process. Simply measuring and recording […]

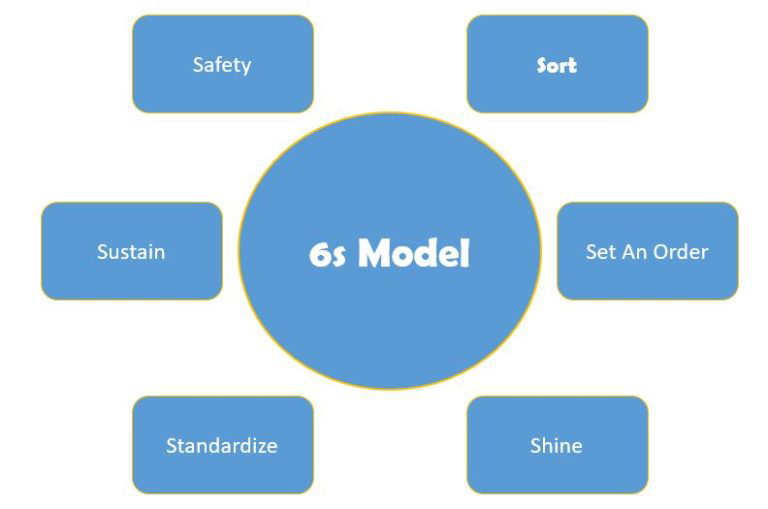

Easy Warehouse Improvement Idea: Apply 6S

6S has long been part of successful manufacturing processes. A natural extension is applying these principles in warehousing and distribution. The pillars of 6S are: Sort – eliminate whatever is not needed Set In Order – organize, identify and arrange everything in a work area Shine – regular cleaning and maintenance Standardize – make it […]

Welcome To Our New Blog Section!

Impact WMS is your partner for warehouse management solutions. But we realize not all solutions depend on technology to enable sustainable results. In the coming weeks, we introduce and discuss many easy and often low tech ways to help you improve your warehouse performance. Specifically, we cover 10 topics: Apply 6S Measurement Space Utilization Slotting […]