WMS Benefit Categories

Numerous benefit categories result from successfully using a warehouse management system (WMS). The categories have varying levels of savings associated with each and can be characterized as tangible or intangible. A tangible savings is a quantitative dollar figure directly related to a specific action or process impacted by the WMS. For example, hardware for a […]

Directed Put-away – Caution

In recent months we outlined several advantages of using a warehouse management system (WMS) to direct product putaway to minimize operator decision making requirements. We pointed out the potential improvements in compliance, operator productivity, and overall space utilization. But as the saying goes, there is no such thing as a free lunch. In this example […]

Put-away, Directed vs. Suggested

In recent months we outlined several advantages of using a warehouse management system (WMS) to direct product putaway to minimize operator decision making requirements. We pointed out the potential improvements in compliance, operator productivity, and overall space utilization. But as the saying goes, there is no such thing as a free lunch. In this example […]

Directed Put-away – No Location Found

In recent posts we discussed taking advantage of technology to help with product put-away. Directed put-away removes the routine and tedious decision making tasks from operators allowing them to be more productive. A good warehouse management system (WMS) should allow management to define various put-away rules the computer will use when determining the best put-away […]

Online Learning Opportunities

The COVID pandemic has changed the way business is done. More working from home and less professional interaction, but you still want to network and continue learning. A positive coming out of the shift in socializing is the numerous online professional development opportunities available. The Association for Supply Chain Management, Atlanta Chapter, has been collecting […]

Implement a Vendor Compliance Program

When you consider the average warehouse receives, counts, and inspects thousands of items of varying shapes and sizes from hundreds of vendors whose picking, packing, and shipping practices are all different, it is not surprising receiving can be one of the most complicated functions in the warehouse. You’ve probably heard reference to the GIGO concept. […]

Is your Warehouse productive?

Most people want to do a good job, know where they stand, and be recognized for their performance. One easy way to accomplish this and also improve productivity is to develop a simple process measuring performance and posts results in the warehouse. It does not have to be a complicated process. Simply measuring and recording […]

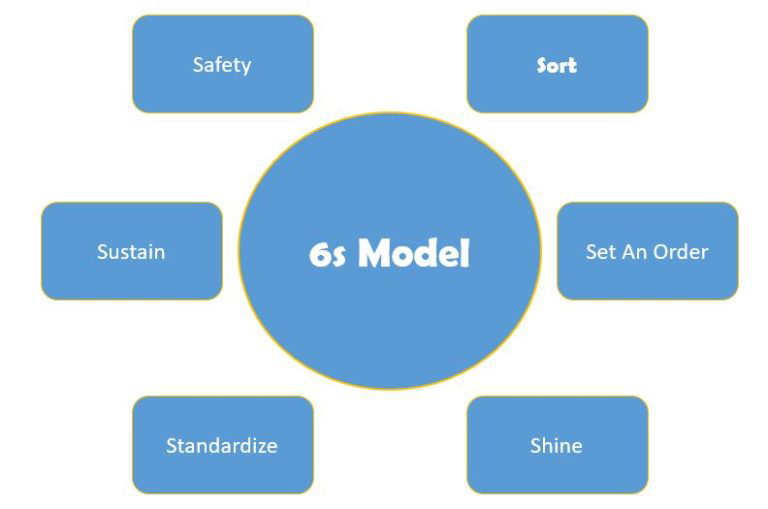

Easy Warehouse Improvement Idea: Apply 6S

6S has long been part of successful manufacturing processes. A natural extension is applying these principles in warehousing and distribution. The pillars of 6S are: Sort – eliminate whatever is not needed Set In Order – organize, identify and arrange everything in a work area Shine – regular cleaning and maintenance Standardize – make it […]