Benefits of Real-Time Warehouse Visibility

Between surging labor costs, a shortage of workers, and facility rents climbing across North America, there’s not a warehousing operation today that isn’t operating with ever shrinking margins. Fortunately, a warehouse manager can harness the benefits of real-time visibility that can have a dramatic effect on the bottom line. WHAT IS REAL-TIME VISIBILITY OF WAREHOUSE […]

What is a Cycle Count?

Your warehouse is full of inventory, but how do you get an accurate picture of what is on any given shelf tomorrow? Next week? Later this afternoon? You could get your warehouse staff to conduct a physical inventory, auditing your entire facility’s stock. But unless you are running a small operation with limited SKUs, a […]

The Benefit WMS Building Blocks – Inventory Accuracy

A Warehouse Management System (WMS) is a foundation for improved operational efficiency, providing a series of building blocks that will act as a basis for efficient warehousing operations. Today we will look at one of the primary building blocks a WMS provides; Improved inventory record accuracy and the reduction in data processing errors that result […]

WMS Benefit Classification

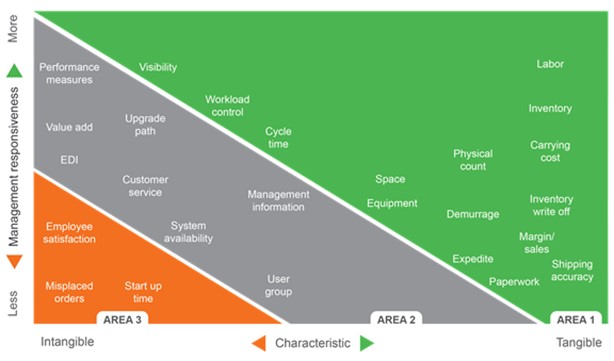

Along with the tangible and intangible characteristics, a benefit should be measured on management’s general level of responsiveness to the benefit. The level of aggressiveness to use in pursuing the benefit will vary by company and/or project. It is critical to discern, in advance, management’s willingness to consider the presented benefits. For example, improved customer […]

Directed Put-away – Caution

In recent months we outlined several advantages of using a warehouse management system (WMS) to direct product putaway to minimize operator decision making requirements. We pointed out the potential improvements in compliance, operator productivity, and overall space utilization. But as the saying goes, there is no such thing as a free lunch. In this example […]

Put-away, Directed vs. Suggested

In recent months we outlined several advantages of using a warehouse management system (WMS) to direct product putaway to minimize operator decision making requirements. We pointed out the potential improvements in compliance, operator productivity, and overall space utilization. But as the saying goes, there is no such thing as a free lunch. In this example […]

Directed Put-away – No Location Found

In recent posts we discussed taking advantage of technology to help with product put-away. Directed put-away removes the routine and tedious decision making tasks from operators allowing them to be more productive. A good warehouse management system (WMS) should allow management to define various put-away rules the computer will use when determining the best put-away […]

The Golden Zone

In August 2020, we discussed the concept of slotting using ABC profiling to help improve productivity in the warehouse (Know Your ABCs). The example provided focused on reducing pick travel distance and time by keeping the fast moving “A” items near the shipping dock, “B” items in the middle of the building, and “C” items […]

Get Involved

Over the past eleven months we reviewed several low-hanging fruit process improvement concepts to help improve your warehouse performance. You can read more about these concepts here. While there are many more ideas we could discuss for consideration in your facility, the final item on our list is Get Involved. More specifically, get involved with learning and […]