Benefits of Real-Time Warehouse Visibility

Between surging labor costs, a shortage of workers, and facility rents climbing across North America, there’s not a warehousing operation today that isn’t operating with ever shrinking margins. Fortunately, a warehouse manager can harness the benefits of real-time visibility that can have a dramatic effect on the bottom line. WHAT IS REAL-TIME VISIBILITY OF WAREHOUSE […]

The Golden Zone

In August 2020, we discussed the concept of slotting using ABC profiling to help improve productivity in the warehouse (Know Your ABCs). The example provided focused on reducing pick travel distance and time by keeping the fast moving “A” items near the shipping dock, “B” items in the middle of the building, and “C” items […]

Cluster Pick When Possible

A straight-forward way to improve pick labor productivity is to eliminate the travel back and forth to the office and the shipping/packaging areas between order picks. One way to accomplish this is to have one operator pick multiple orders at the same time, or Cluster Pick, if possible. Cluster Picking is a pick method where […]

Know Your Order Profile

A basic principle to optimizing warehouse space is evaluating and selecting the most space efficient storage equipment. Using more dense storage equipment is a key factor to reduce space requirements. An analysis of your products inventory levels and cubic order activity should be performed to accurately define the storage requirements in reserve and the forward […]

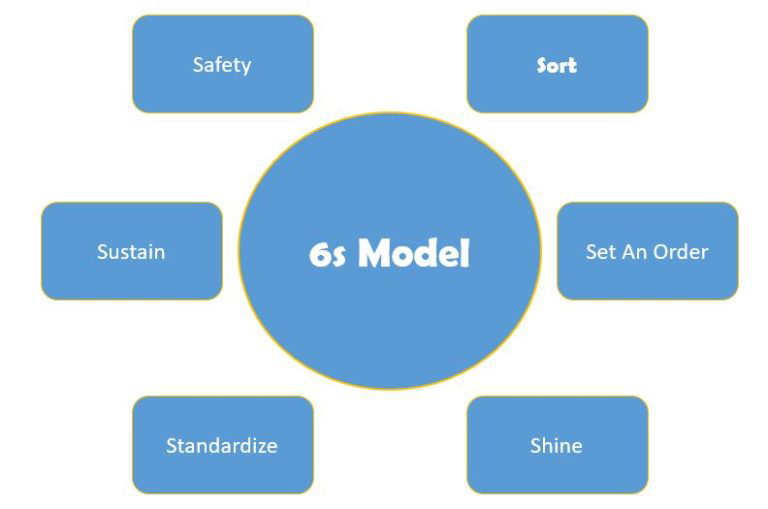

Easy Warehouse Improvement Idea: Apply 6S

6S has long been part of successful manufacturing processes. A natural extension is applying these principles in warehousing and distribution. The pillars of 6S are: Sort – eliminate whatever is not needed Set In Order – organize, identify and arrange everything in a work area Shine – regular cleaning and maintenance Standardize – make it […]