Implement a Vendor Compliance Program

When you consider the average warehouse receives, counts, and inspects thousands of items of varying shapes and sizes from hundreds of vendors whose picking, packing, and shipping practices are all different, it is not surprising receiving can be one of the most complicated functions in the warehouse. You’ve probably heard reference to the GIGO concept. […]

Store Product Picked Together, Together

In an earlier blog we discussed ABC profiles and cube movement distribution. Through this analysis you should be able to determine if products are frequently ordered together. If you do see a significant correlation between products, consider storing the products together to help reduce overall travel time per pick tour. If the pick correlation frequency […]

Cluster Pick When Possible

A straight-forward way to improve pick labor productivity is to eliminate the travel back and forth to the office and the shipping/packaging areas between order picks. One way to accomplish this is to have one operator pick multiple orders at the same time, or Cluster Pick, if possible. Cluster Picking is a pick method where […]

Warehouse within a Warehouse

Using a Forward Pick strategy helps keep a smaller volume of inventory in easily accessible bins (Forward Pick) with the excess stock in remote bins (Reserve Storage) (Figure 1). The Forward Pick zone in a warehouse functions as a “warehouse within a warehouse”: many of the most popular SKUs are stored there in small amounts, […]

Know Your Order Profile

A basic principle to optimizing warehouse space is evaluating and selecting the most space efficient storage equipment. Using more dense storage equipment is a key factor to reduce space requirements. An analysis of your products inventory levels and cubic order activity should be performed to accurately define the storage requirements in reserve and the forward […]

Know Your ABCs

Paying attention to the fastest selling items to make sure they are located in the most advantageous picking position will generate significant labor cost savings. If available space is a concern, slotting will also help improve storage utilization by focusing on the slowest movers to see if their assigned bin space can be reduced. Slotting […]

Space Utilization Part Two

In Part two of our Space Utilization series, “The Supply Chain Doctor” Chris Barnes discusses more ways you can utilize space in your Warehouse. Think Cubic Feet The impact of using vertical storage space depends on your current storage clear height and product stack-ability restrictions. For example, in the beverage industry, a stack height limitation […]

Space Utilization Part One

Do you have too much warehouse space? Chances are you are either out of space or getting close to it. It happens all the time, inventory (and other stuff) tends to expand to fill the amount of available space. When you do run out of warehouse space there are many options to consider including expanding […]

Who are Korber? What you need to know as a Impact WMS Customer.

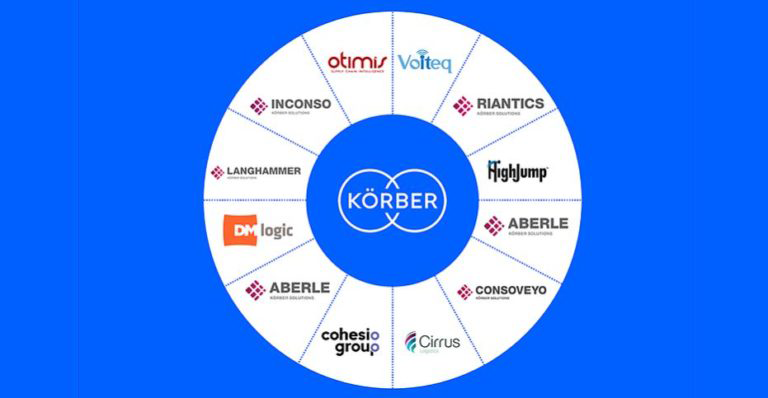

In August 2017, Körber acquired HighJump, which is now managed under its business area, Körber Supply Chain. Körber brings together a number of companies, including 12 supply chain technology providers (four in automation and eight in software and consulting). These 12 providers include two WMS providers that have multiple WMS solutions. HighJump (named Körber since […]

Is your Warehouse productive?

Most people want to do a good job, know where they stand, and be recognized for their performance. One easy way to accomplish this and also improve productivity is to develop a simple process measuring performance and posts results in the warehouse. It does not have to be a complicated process. Simply measuring and recording […]