What Does A Warehouse Manager Manage

I recently spoke with a warehouse manager who bluntly told me the three things she has to control and manage: LABOR Labor has a big impact on budget and can be scheduled as needed at a local level. If you see projected inbound or outbound activity in the near term you can work to get […]

Protected: Class Demonstration

The Benefit WMS Building Blocks – Inventory Accuracy

A Warehouse Management System (WMS) is a foundation for improved operational efficiency, providing a series of building blocks that will act as a basis for efficient warehousing operations. Today we will look at one of the primary building blocks a WMS provides; Improved inventory record accuracy and the reduction in data processing errors that result […]

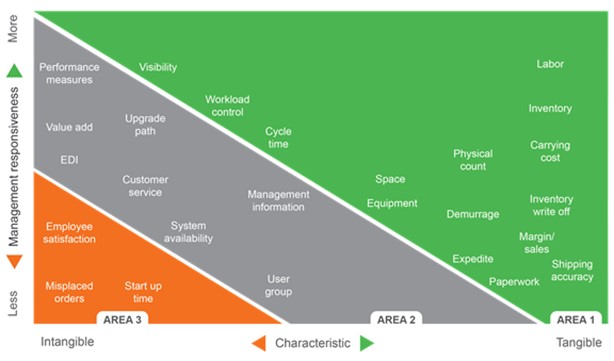

WMS Benefit Classification

Along with the tangible and intangible characteristics, a benefit should be measured on management’s general level of responsiveness to the benefit. The level of aggressiveness to use in pursuing the benefit will vary by company and/or project. It is critical to discern, in advance, management’s willingness to consider the presented benefits. For example, improved customer […]

WMS Benefit Categories

Numerous benefit categories result from successfully using a warehouse management system (WMS). The categories have varying levels of savings associated with each and can be characterized as tangible or intangible. A tangible savings is a quantitative dollar figure directly related to a specific action or process impacted by the WMS. For example, hardware for a […]

The Road Ahead: Justifying a WMS

A successful warehouse management system (WMS) implementation can provide an 18-24 month return on investment. A WMS also serves as a foundation for instituting a continuous improvement culture and facilitates on-going annual benefits ranging from 5-10%. For some companies, justification in a WMS is a matter of survival. Having the right material available at the […]

Directed Put-away – Caution

In recent months we outlined several advantages of using a warehouse management system (WMS) to direct product putaway to minimize operator decision making requirements. We pointed out the potential improvements in compliance, operator productivity, and overall space utilization. But as the saying goes, there is no such thing as a free lunch. In this example […]

Put-away, Directed vs. Suggested

In recent months we outlined several advantages of using a warehouse management system (WMS) to direct product putaway to minimize operator decision making requirements. We pointed out the potential improvements in compliance, operator productivity, and overall space utilization. But as the saying goes, there is no such thing as a free lunch. In this example […]

Directed Put-away – No Location Found

In the December 2021 post we outlined the potential need for operators to override the system directed put-away instructions and the need for having a “trouble” location. In both these examples the primary objective is to keep operators moving and processing productive tasks, in this case putting product away and moving to the next task. […]

Directed Put-away – No Location Found

In recent posts we discussed taking advantage of technology to help with product put-away. Directed put-away removes the routine and tedious decision making tasks from operators allowing them to be more productive. A good warehouse management system (WMS) should allow management to define various put-away rules the computer will use when determining the best put-away […]